A ground loop design for either boreholes, whether standard or double U-tubes or Twisters, or horizontal is $125. I’ll do various iterations to suit your needs. A connection drawing to a forced air type HP, showing proper pipe and pump sizes suited to your specific job is $120 for each HP. A hydronic mech room drawing (for radiant or combo) systems is $500 (and up) Thegeoguy

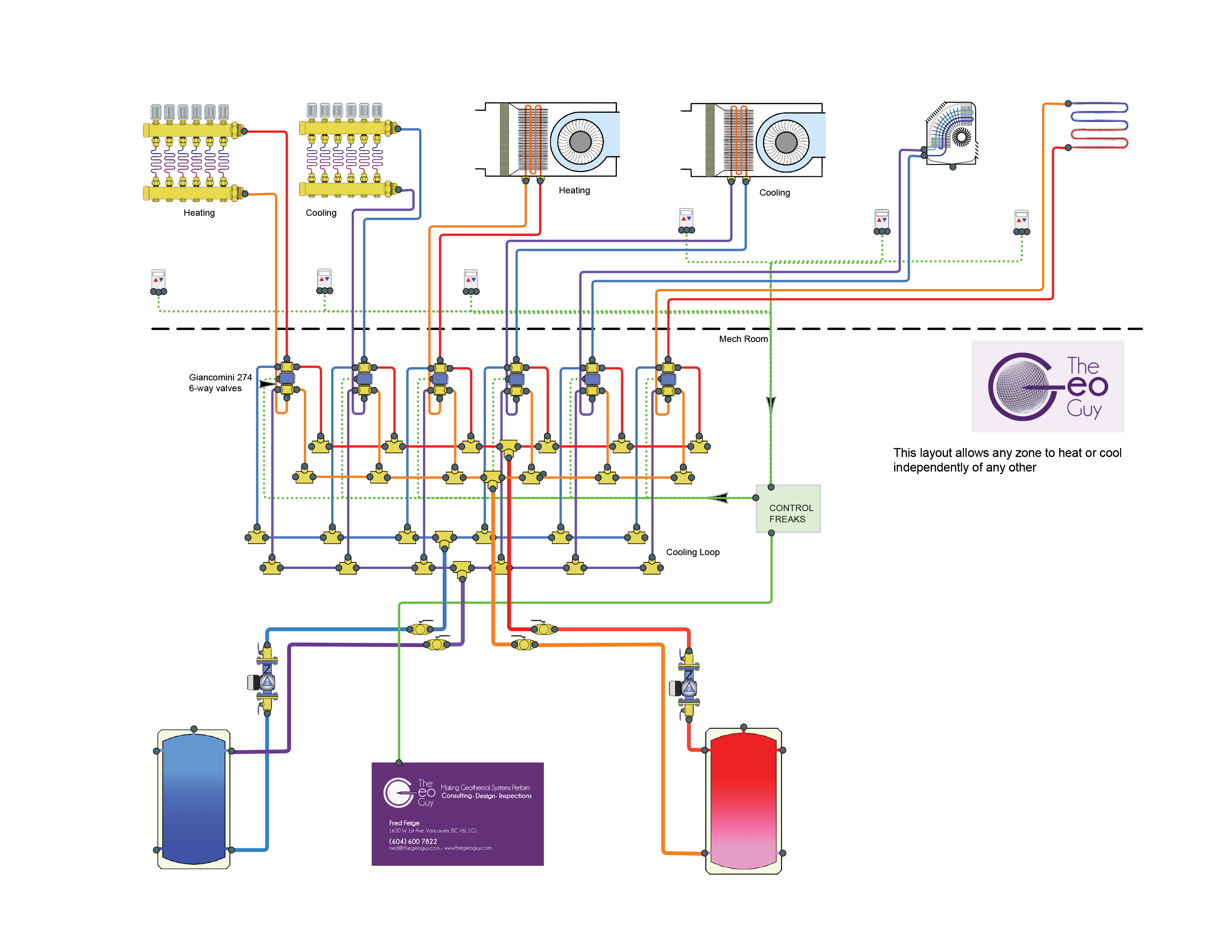

If you’re building a large home with both heating and cooling loads, you may want to try the ultimate geo system. Typically the HP runs in heating mode and then transfers over to cooling mode when required. Hopefully you have 2 buffer tanks for this unless you only need a seasonal transfer. A heat pump inherently produces both hot and cold at the same time. Why not use that and get COPs beyond belief. The challenge is piping it and controlling it. Here is a sample system:

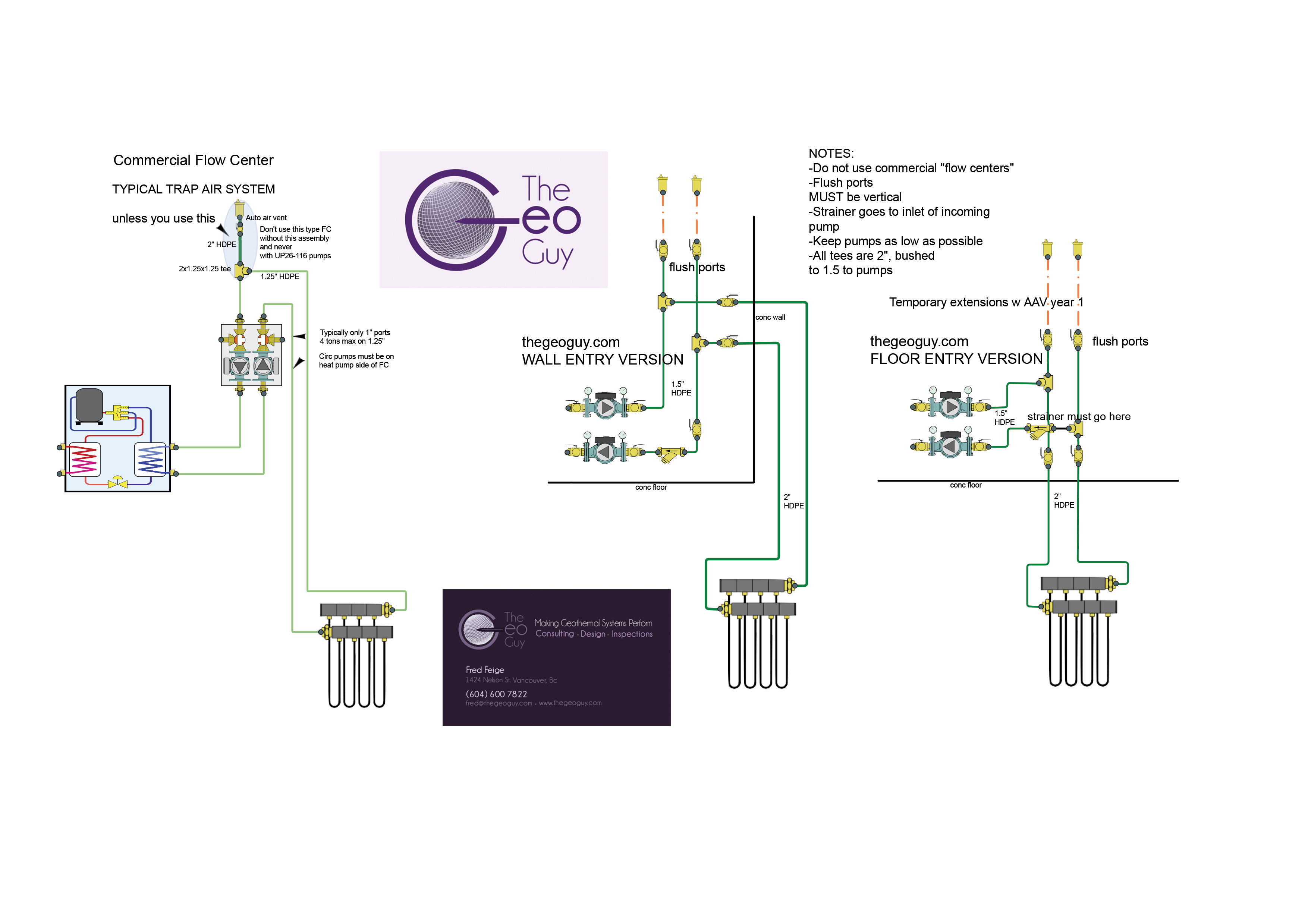

While most installers use ready built “pump packs” or “flow centers” they have serious limitations. The typical models using 1 inch 3 way valves are good to 4 tons. On 5 tons and up these units have too high a pressure drop. 5 tons and up needs 1.5″ or 2″ piping to the G-loop to be energy efficient. They only come with the single speed pumps too. If you get one that uses Grundfos UP26-116 please return it as it’s Grundfos biggest pump hog. While doing service work I noticed (heard) every single loop I ever saw had air in it except 1 but the installer since died. A common alternate was the “non pressure” system which has its own flaws. 2 pumps immediately in series causes the first one to send turbulent water to the next pump, impacting its output. And then what about the requirement for positive pressure…

New or retrofit? Both require a heat loss calculation or damn good estimate if retrofit. Retrofits often require duct upgrades if coming from a fossil fuel furnace. What is the size of home and size of property? This determines heat pump (HP) and loop size. Bigger homes always perform better with mulitple HP’s. Location. Your precise address helps but often the nearest big-ish city is needed since not every little town is available for climate data. Water bodies, soil conditions, and local knowledge help too. Forced air or radiant floors? Forced air is relatively simple but is hard to zone, radiant or hydronic systems require a mech room and many more parts but offer superior comfort and lower run costs. Horizontal or vertical loops? Vertical is almost always better but usually more expensive but sometimes not. Deeper and fewer holes are always better. However vertical is cheaper in the very…

Around here we do things a little differently, but Twisted? The first borehole geo system I ever saw hurt. Reason being I was the drillers helper and it’s hard work especially for a 150 lb scrawny guy. Looking at the hole with 2 pipes randomly in it surrounded by grout which has a thermal conductivity ranging from near styrofoam all the way up to better than styrofoam, I figured there must be a better approach. There were methods to improve the TC of the grout (thermal conductivity) up from around .4 to .8 or better. A good TC in rock is maybe 2.0 so you get the point of the styrofoam. I started researching and formulating my own grout materials and even tried graphite, so messy. At a trade show in Germany I saw a double U-tube for the first time. It uses spacers to hold the 4 pipes up…

Horizontal loops are popular for a few reasons: They are generally considered to be cheaper to install. This is not necessarily true. Their performance is considered to be just as good as vertical boreholes. Wrong. They can be squished closer together as in slinky loops. Dead wrong. They can be economically installed at the time of construction since an excavator is already there. A maybe. Drawbacks to Horizontal Loops: Horizontal loops are always installed in the overburden layer of your soil/property. This means the thermal conductivity of the soil ranges from barely ok to abysmal. See the chart below. We see from this chart that an average sand/clay/whatever horizontal overburden has a TC value of 0.5 whereas rock has a value of 1.5 to 2. This simple arithmetic alone should pretty much discredit anyone doing horizontal loops. Any horizontal loop shallower than 20 ft still shows a seasonal swing whereas…

More is always better! “Less is a disaster” – Stan Marco It seems that in geo design everyone is always trying to design the smallest loop possible to save money. Are they saving money? The answer is a clear NO. My son the physicist says that I should quantify things instead of ranting, so here goes… On the accompanying chart of a typical WaterFurnace unit, it shows 30degF and 40degF EWT, (entering water temp) and the accompanying heat output, 29,700 Btu/hr and 33,900 respectively. The longer loop length gives you a higher EWT. At a typical 2500 hrs/year of run time, we get a difference of 4,200 Btu/hr x 2500 hrs = 10,500,000 Btu/year more heat. That was 10.5 million Btu’s! This translates to a reduced runtime of 10.5mBtu/yr / 33,900Btu/hr = 310 run hours/yr for the same load. Nice! 310 saved runs hours/year cost 2.52kW (from the chart) x…

Whether you have a greenhouse or indoor grow operation, whether for medical marijuana, recreational cannabis, or micro greens for restaurants, proper climate control is as vital as knowing how to grow your crop. The levels of heating and cooling and dehumidification are from 4 to 10 times higher in a greenhouse or grow room than in a residential home application. This means some serious climate control equipment and design is required. Greenhouses typically use fans and vents for cooling. This means all that heat energy is expelled and wasted only to be bought back at night for heating from your local utility. This energy can be saved and reused. Forget about humidity control and co2, gone with the wind via the fans. In a closed grow room the lights do more than enough heating and the room needs to be cooled. When the lights go out the temp falls quickly…

The high cost of geo systems, a must read! Hello — Glad to hear you’re busy – thanks for answering — I installed my own ground loop & 4-ton Command Air in 1988. After a burn-out in 1998, I put in a new 4-ton Command Air w/scroll compressor. All the time hooked into my original loop, consisting of 4-each 500′ loops hooked in parallel, with two Grundfos pumps in series, giving me aprox 12 gpm. the compressor typically locks-out a few times in January, but this year it had been a plague, with me having to reset at least once a day — have been considering putting a 1 hour time delay triggered by the lockout relay. I sent for a digital temperature probe. So I need to take some accurate temp and pressure drop measurements. After I get that done, I may need some serious advice as to how…

A reader sent pics and a description of his failed 6 ton open well, forced air geo system: The GeoGuy responds… I finally had a chance to get to this and don’t really have a good answer… The workmanship from what I can see is bordering criminal and you should notify Climatemaster to have this jerks dealer status revoked. It’s so sad that there are no licensing requirements for residential hvac in most areas. Your mech room is very small I’m wondering what room we have to add some components… You will need to add a closed loop to protect the HP from the skanky well water you have. This will take up some space. Is there a zoning module installed? In other words you simply cannot open and close air dampers via thermostats on a heat pump without maintaining airflow through the unit. The different brands of thermostats suggest…

Beware of the low bid. In the big league, when the bids come in, usually the lowest bid and the highest bid are tossed out. There is good reason for this. The value of a proposal is clearly not just the price, but what you get for the money. The client expects good value, professional workmanship, and a problem free relationship with the contractor/provider of the service. If there is a problem, it usually costs money to resolve and there goes the savings in choosing the low bid. Checking out the references and the reputation of the contractor cannot be emphasized enough. QUALIFICATIONS: The qualifications of the geo contractor are very important. In the electrical world permits and licenses are clearly defined. In the plumbing world permits and licenses are clearly defined. In the hvac world it’s the Wild West. What are the qualifications of your low bid geo contractor?…

Making Geothermal Projects Work. The core of the Earth is kept hot by radioactive decay while the surface is kept warm by solar radiation. Geothermal “energy” is extracted from the depths of the Earth while geothermal heating and cooling (now called geoexchange) is extracted from the surface of the Earth. This is why we refer to the Earth as our free solar energy storage system from which we can exchange low level energy at will.

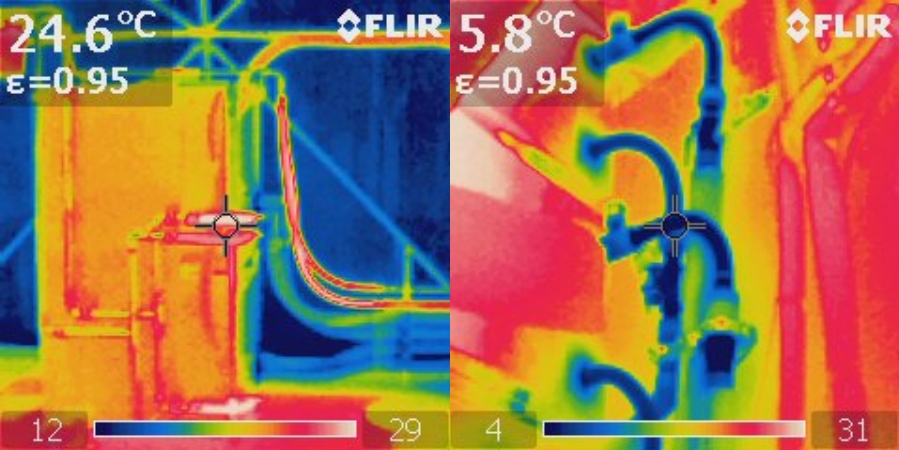

Geothermal Heating and Cooling is clearly visible when we use different eyes. On the left are 2 stacked 5 ton units in a greenhouse. On the right are 2 stacked 4 ton units in a home. The Geo Guy can do energy audits like this infra-red imaging to find where your energy is going. WARNING: IR imaging shows how badly we build things here.

This twin 5 ton HP system performs! Each HP has its own lake loop 1,100ft away using only 2 small circulator pumps for each. It does radiant floor heating for 3 buildings, DHW and a pool.