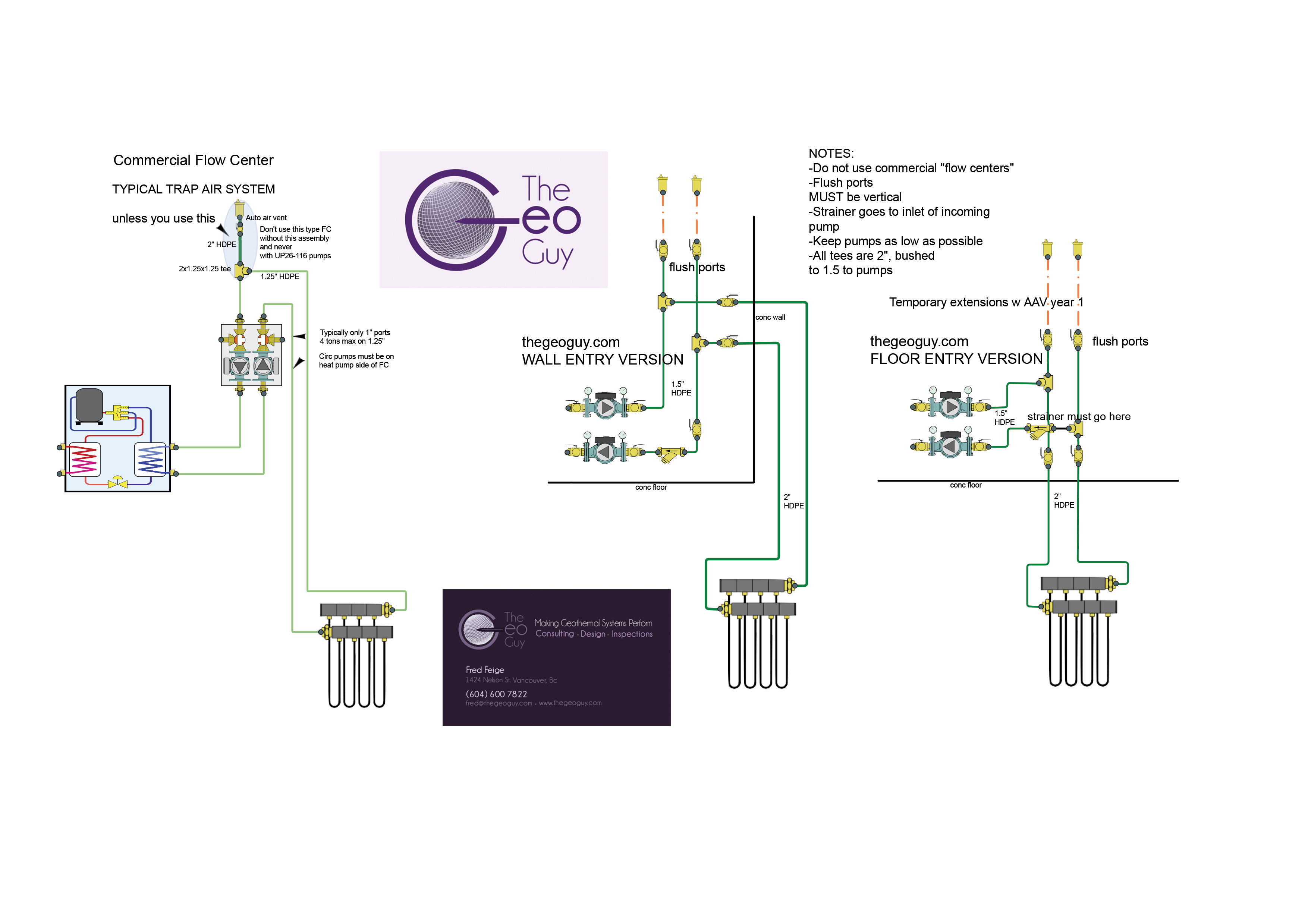

While most installers use ready built “pump packs” or “flow centers” they have serious limitations. The typical models using 1 inch 3 way valves are good to 4 tons. On 5 tons and up these units have too high a pressure drop. 5 tons and up needs 1.5″ or 2″ piping to the G-loop to be energy efficient. They only come with the single speed pumps too. If you get one that uses Grundfos UP26-116 please return it as it’s Grundfos biggest pump hog.

While doing service work I noticed (heard) every single loop I ever saw had air in it except 1 but the installer since died. A common alternate was the “non pressure” system which has its own flaws. 2 pumps immediately in series causes the first one to send turbulent water to the next pump, impacting its output. And then what about the requirement for positive pressure on the inlet side? Their rated outputs are deceptive, all it takes is a flow meter to prove that. I like to see 30 psi in the G-loop.

Using the attached drawing you (or I) can select whatever pumps you need and get 3 speed models to fine tune the flow rate. While the flush ports shown may be inconveniently located pointing up, they capture the air in the loop continuously. Micro bubbles take months to come out, not the 20 minute recommended flush time.

Should you cheap out and use PVC piping please avoid the adapters with male threads, I’ve seen so many broken off. You may have better luck using Sch 80 fittings there.

Happy Pumping from TheGeoGuy.